U series

GRANDEMAC

| Color: | |

|---|---|

| Availability: | |

| Quantity: | |

---------★Product Introduction★---------

Product features of the U series rotary tiller

Function:

Making seedbeds in soil after flipping and loosening

Benefits:

Suitable for seedbed operations with high requirements for soil crushing degree

The work effect is still significant in harsh conditions, such as hard land, paddy fields, etc

Significant mixing/pressing function

Simple structure and easy maintenance

advantage:

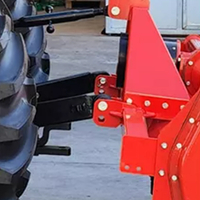

The transmission shaft comes with a clutch hub as standard to prevent equipment damage from overload

540 single speed gearbox, with a total of 4 blade shaft speeds to choose from by adjusting different combinations of gear pairs

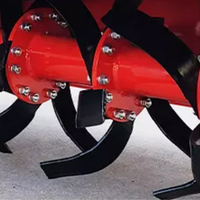

Each disc has 6 blades, which provides better soil crushing effect when rotated

Side gear transmission, oil bath lubrication

The sealing of the gearboxes on both sides of the blade shaft adopts floating oil seals, which are waterproof and dustproof

The pressure of the retaining plate can be adjusted by a spring

In areas with multiple stones or hard soil conditions, the cutterhead can be optionally equipped with a docking flange type

---------★Product Specification★---------

MODEL NUMBER |

HORSEPOWER |

MACHINE WIDTHS |

MACHINE WEIGHT |

NUMBER OF BLADES |

COLORS |

U-130 | 35-80HP | 146CM | 380KG | 8 |  |

U-140 | 40-80HP | 156CM | 400KG | 8 |  |

| U-150 | 45-80HP | 171CM | 420KG | 8 |  |

| U-180 | 50-80HP | 196CM | 460KG | 8 |  |

| U-205 | 60-80HP | 221CM | 500KG | 8 |  |

| U-230 | 70-80HP | 246CM | 550KG | 8 |

|

VIDEO PRESENTATION

---------★Our Advantages★---------

●Heavy duty multi-speed gearbox, standard with backup gear, input speed: 540/750/1000rpm, 8 types of cutter shaft speeds adjustable

●There are three models of rotary tillers available for selec-tion, including the C-type and L-type rotary tiller blades with universal axes

●The rotary tiller blades are spiral arranged on the blade shaft, rotating smoothly, and the soil is evenly and finely broken

●Side gear transmission, oil bath lubrication

●The bearing boxes on both sides of the cutter shaft are equipped with floating oil seals, which are waterproof and dustproof

●The maximum supporting power reaches 120hp

---------★Packaging and Transportation★---------

| packaging | genuine packaging | |||

| according to customers' request | ||||

| nude packaging | ||||

| standard export pacakging | ||||

| shipping | by express | DHL, FEDEX, UPS, TNT, ect. | ||

| by air | China main port | |||

| by sea | China main port | |||

| payment | TT, western union, credit card, Alibaba trade assurance, ect. | |||

---------★FAQ★---------

We are based in Jiangsu, China, start from 2019,sell to Africa(60.00%),South America(30.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

Always final Inspection before shipment;

Our products include agricultural planting machinery such as soil tillage, weeding, fertilization, sowing, spraying, rotary tillage, transportation, etc.

30% payment in advance by TT, 70% balance before delivery.

For more info, please go to Features & Photos on this page ↑↑↑

TIPS: How to maintain the rotary tiller normally?

1. Daily maintenance

Cleaning: After each use, promptly remove soil, weeds, and other debris from the rotary tiller, especially the blades and gear parts.

Inspection: Regularly inspect all components of the rotary tiller, including blades, gears, drive shafts, chains, etc., to ensure that there is no looseness, wear, or damage.

2. Lubrication

Lubricating oil: Regularly inspect and replace lubricating oil, especially in the transmission and bearing parts, to ensure good lubrication and reduce wear.

Lubricating grease: For parts that require lubricating grease, such as chains and gears, regularly add an appropriate amount of lubricating grease according to the instructions.

3. Blade maintenance

Check the blade: Regularly check the wear of the blade. If the blade becomes dull or damaged, replace or grind it in a timely manner.

Tighten the blade: Check the fastening bolts of the blade to ensure they are secure and prevent loosening or detachment during operation.

4. Maintenance of transmission system

Belt inspection: Regularly check the tension and wear of the transmission belt, and adjust or replace it if necessary.

Chain maintenance: Check the tightness and lubrication of the chain, adjust and lubricate it in a timely manner, and maintain good working condition.

5. Storage

Dry environment: Store the rotary tiller in a dry environment to avoid prolonged exposure to moisture and harsh weather conditions, in order to prevent rusting and corrosion.

Cover protection: When not in use, a dust cover or canvas can be used to cover the rotary tiller to reduce the impact of dust and moisture on the equipment.

---------★Product Introduction★---------

Product features of the U series rotary tiller

Function:

Making seedbeds in soil after flipping and loosening

Benefits:

Suitable for seedbed operations with high requirements for soil crushing degree

The work effect is still significant in harsh conditions, such as hard land, paddy fields, etc

Significant mixing/pressing function

Simple structure and easy maintenance

advantage:

The transmission shaft comes with a clutch hub as standard to prevent equipment damage from overload

540 single speed gearbox, with a total of 4 blade shaft speeds to choose from by adjusting different combinations of gear pairs

Each disc has 6 blades, which provides better soil crushing effect when rotated

Side gear transmission, oil bath lubrication

The sealing of the gearboxes on both sides of the blade shaft adopts floating oil seals, which are waterproof and dustproof

The pressure of the retaining plate can be adjusted by a spring

In areas with multiple stones or hard soil conditions, the cutterhead can be optionally equipped with a docking flange type

---------★Product Specification★---------

MODEL NUMBER |

HORSEPOWER |

MACHINE WIDTHS |

MACHINE WEIGHT |

NUMBER OF BLADES |

COLORS |

U-130 | 35-80HP | 146CM | 380KG | 8 |  |

U-140 | 40-80HP | 156CM | 400KG | 8 |  |

| U-150 | 45-80HP | 171CM | 420KG | 8 |  |

| U-180 | 50-80HP | 196CM | 460KG | 8 |  |

| U-205 | 60-80HP | 221CM | 500KG | 8 |  |

| U-230 | 70-80HP | 246CM | 550KG | 8 |

|

VIDEO PRESENTATION

---------★Our Advantages★---------

●Heavy duty multi-speed gearbox, standard with backup gear, input speed: 540/750/1000rpm, 8 types of cutter shaft speeds adjustable

●There are three models of rotary tillers available for selec-tion, including the C-type and L-type rotary tiller blades with universal axes

●The rotary tiller blades are spiral arranged on the blade shaft, rotating smoothly, and the soil is evenly and finely broken

●Side gear transmission, oil bath lubrication

●The bearing boxes on both sides of the cutter shaft are equipped with floating oil seals, which are waterproof and dustproof

●The maximum supporting power reaches 120hp

---------★Packaging and Transportation★---------

| packaging | genuine packaging | |||

| according to customers' request | ||||

| nude packaging | ||||

| standard export pacakging | ||||

| shipping | by express | DHL, FEDEX, UPS, TNT, ect. | ||

| by air | China main port | |||

| by sea | China main port | |||

| payment | TT, western union, credit card, Alibaba trade assurance, ect. | |||

---------★FAQ★---------

We are based in Jiangsu, China, start from 2019,sell to Africa(60.00%),South America(30.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

Always final Inspection before shipment;

Our products include agricultural planting machinery such as soil tillage, weeding, fertilization, sowing, spraying, rotary tillage, transportation, etc.

30% payment in advance by TT, 70% balance before delivery.

For more info, please go to Features & Photos on this page ↑↑↑

TIPS: How to maintain the rotary tiller normally?

1. Daily maintenance

Cleaning: After each use, promptly remove soil, weeds, and other debris from the rotary tiller, especially the blades and gear parts.

Inspection: Regularly inspect all components of the rotary tiller, including blades, gears, drive shafts, chains, etc., to ensure that there is no looseness, wear, or damage.

2. Lubrication

Lubricating oil: Regularly inspect and replace lubricating oil, especially in the transmission and bearing parts, to ensure good lubrication and reduce wear.

Lubricating grease: For parts that require lubricating grease, such as chains and gears, regularly add an appropriate amount of lubricating grease according to the instructions.

3. Blade maintenance

Check the blade: Regularly check the wear of the blade. If the blade becomes dull or damaged, replace or grind it in a timely manner.

Tighten the blade: Check the fastening bolts of the blade to ensure they are secure and prevent loosening or detachment during operation.

4. Maintenance of transmission system

Belt inspection: Regularly check the tension and wear of the transmission belt, and adjust or replace it if necessary.

Chain maintenance: Check the tightness and lubrication of the chain, adjust and lubricate it in a timely manner, and maintain good working condition.

5. Storage

Dry environment: Store the rotary tiller in a dry environment to avoid prolonged exposure to moisture and harsh weather conditions, in order to prevent rusting and corrosion.

Cover protection: When not in use, a dust cover or canvas can be used to cover the rotary tiller to reduce the impact of dust and moisture on the equipment.